Performance Efficiency is improved by resolving multiple problem points, and ensuring phased approach with technology that helps to ensure an ROI and scalability. Intelligent Asset Optimization can deliver key business goals.

Focusing on minimizing operational and material costs. Reduce overhead and supply chain. Mitigate safety and compliance risks.

Drive speed and agility on the factory floor visibility with agility. Drive speed. Shorten your cycle time to market and fulfill more orders.

Maximize your asset utilization. Reduce inventory levels and capital expenditures. Shorten changeover times.

Our Services are distinct in the market, featuring unmatched time to value, supported by domain expertise, and depth of offerings that can rapidly expand your output.

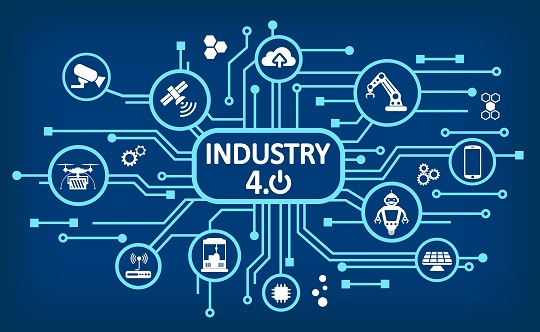

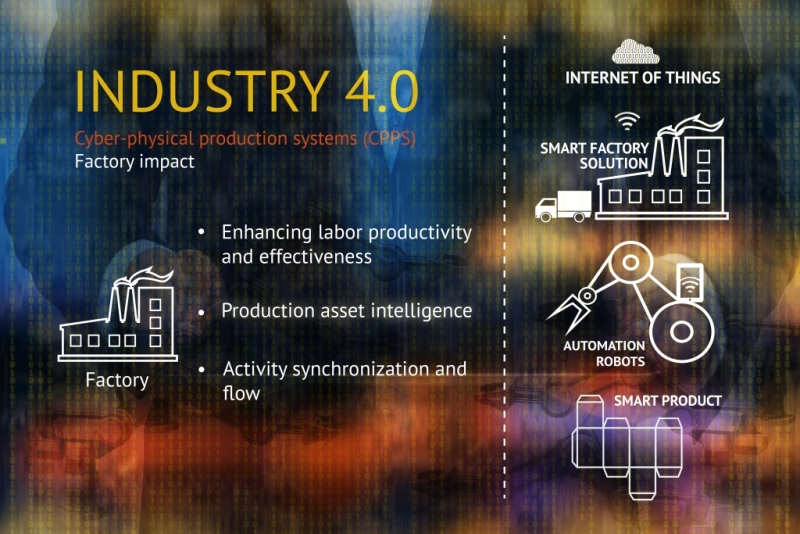

The industrial IoT provides real time data about the overall health and performance of your assets and production lines. And, real-time alerts can help operators quickly address any issues before they become major failures that can cost your plant valuable time and money.

Asset to Asset, line to line comparisons, across plants operations, shifts and more. New Manufacturing Technologies enabled plant benchmarking. It optimizes data accessibility and comparability throughout the manufacturing domain.

Benchmarking performance is done between the various equipment, workers, processes, and yields across various plants, systems are complex and data is opaque. Without clear data visibility , your KPIs, how confident can you be in directing improvements? IoT collect, validate, and interpret data. Plant benchmarking supports substantive improvements in facilities across your entire operation.

Identify potential issues before they happen. Reduce unplanned downtime, increase asset life, and optimize costs.

Deal manufacturing processes with technology—and achieve unmatched throughput and quality.

Predictive maintenance makes equipment more durable and productive.

Increase asset utilization – Monitor asset health in real time to identify abnormal conditions and identify what caused them.

Our production management solutions help manufacturers with the right mix of industrial IoT, AI, and Operational analytics to meet challenges and seek competitive advantage.